WIRE ROPE SLINGS

What Are Wire Rope Slings?

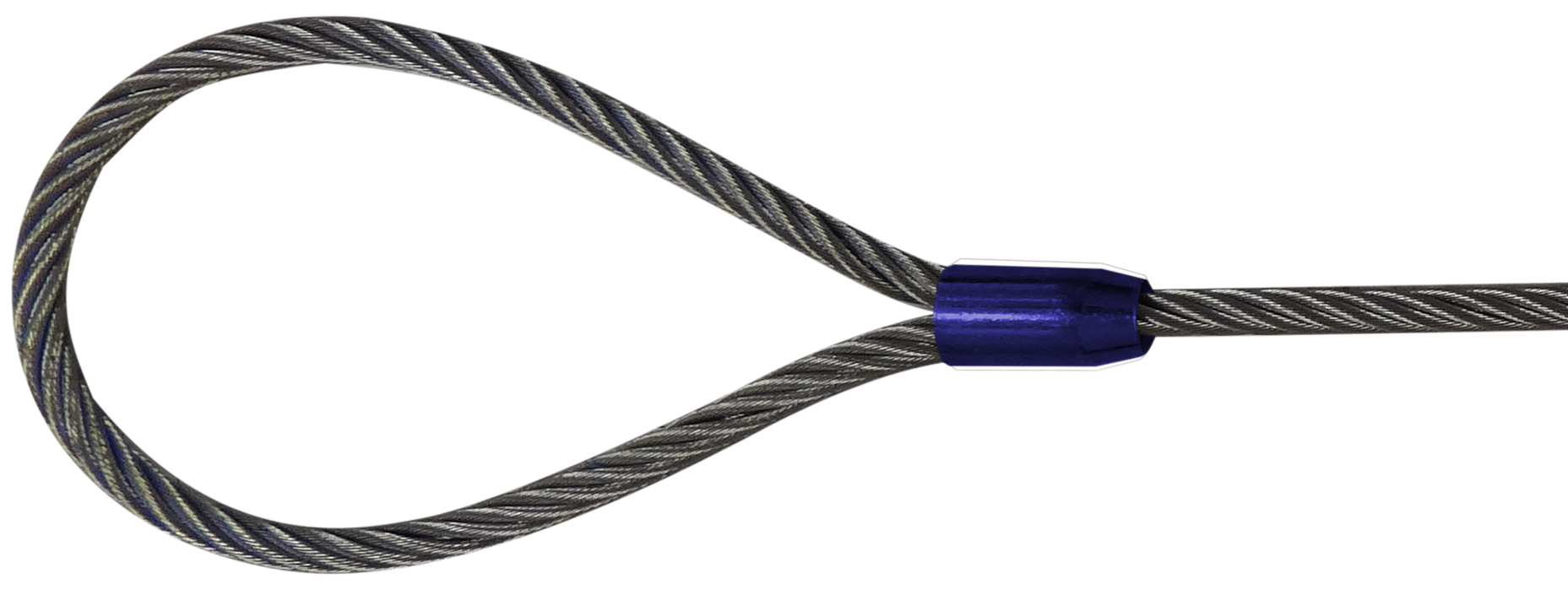

Wire rope slings are designed specifically for heavy-duty jobs like lifting, towing, anchoring loads, and hoisting. They are fabricated in such a way that makes them abrasion and heat resistant. This makes them particularly useful under extreme conditions. Wire rope sling comes in a variety of different types such as single part slings, socketed rope assemblies, braided rope slings, stainless steel slings, and galvanized cable laid slings.

Properties of Wire Rope Slings

Wire rope slings consist of separate wires that have been twisted into strands. These strands are then twisted together to produce a structurally sound rope. To give them more flexibility, wire rope slings sometimes have a fiber core. Wire rope slings are

- Strong and durable

- Able to withstand abrasion

- Pliable or able to bed without distortion

The strength of a wire rope sling and its other properties depend on its size, how it has been constructed, its grade, and the numbers of wires used in its creation.

What Are Wire Rope Slings Used For?

Wire rope slings are generally used for operations that involve lifting heavy loads. They are used in different industries, and they are an important rigging component in the manufacturing industries where heavy-duty shifting and loading of heavy objects are required on a regular basis. The durability of wire rope slings makes them useful in steel mills and forging facilities.

Wire Rope Sling Care & Maintenance

Wire rope, while durable and lubricated during manufacturing, doesn’t last forever. However, with proper care and maintenance, it can last a long time. There are a few things to keep in mind as you're using and storing your wire rope sling.

For starters, wire rope must be re-lubricated throughout its life. Be sure to use a light-bodied lubricant that can be absorbed to the core of the rope. You can apply lubricant by dripping it, spraying it, or brushing it onto the wire rope. The life of your wire rope sling is directly dependent on the effectiveness of your lubrication technique.

What Lubricants Are Best?

The purpose of applying lubricant to your wire rope sling is to reduce friction and protect against corrosion. Because your wire rope is made up of multiple strands, it’s important to make sure that every strand is coated in lubricant after you apply it. Your wire should be pliable and not crack or separate when cold; it shouldn’t drop when warm. While you may consider heavy grease or engine oil to work as lubricant — these substances actually contain materials that can cause more damage to the rope rather than extend its life and use.

Storage & Handling Tips for Your Wire Rope Sling

It’s important to store your wire rope sling correctly when it's not in use. Keep it in an area where there will be absolutely no exposure to water, extreme heat, corrosive fumes, liquids, or sprays. It should also be kept away from any area where there is risk of being run over by a vehicle, kinked, or where other heavy items and loads might be stored on top of it.

In addition to being stored securely and away from potential damages, your wire rope sling should be protected from extreme temperatures at all times. Never use your wire rope in environments over 400°F or below 40°F. If you think that your rope has been exposed to these temperatures, remove it from use immediately, as it may be more susceptible to breaking during use.

Types of Wire Rope Slings

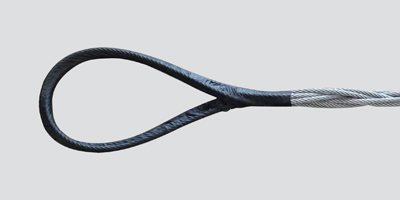

Single-Part

The most common type of wire rope sling. They can be hand- or mechanically-spliced.

Braided

Known for their flexibility, smaller D/d requirements, and higher capacity. Available in 3-, 6-, 8-, and 9-part configurations.

Socketed Assemblies

Characterized by having a spelter or swage socket on each end. Used for more permanent applications.

Grommets

Endless wire rope slings.

Galvanized Cable-Laid

Fabricated with Cable-Laid Cable. Considered more flexible than regular wire ropes.

Stainless Steel

Similar to single-part wire rope slings but with more corrosion resistance. Often used for outdoor applications.

Important Wire Rope Sling Tips to Remember

When it comes to using wire rope slings in or on your jobsite, there are a few things to keep in mind in order to make sure that your wire rope sling is ready for use and that it will last for years to come. For starters, be sure to designate a qualified person to inspect all of your slings, fastenings, and attachment each day before use for damage or defects. A thorough inspection of your wire sling should check for:

- Broken wires

- Severe abrasion or scraping

- Kinking, crushing, or other damages

- Evidence of heat damage

- Damaged attachments

- Severe corrosion

- Any other condition that makes the inspector doubt its reliability or ability to be used safely

In addition to daily inspects and maintenance, be sure to also do regular inspections that check for the following:

- Frequency of sling use

- Severity of service conditions

- Nature of the lifts

- Service life of other slings used for similar circumstances.

By regularly performing these inspections that check the condition of your rope, you’ll not only be able to give your wire rope sling the care and maintenance that it needs to work at its best, you’ll be protecting your entire team and jobsite from the potential dangers that can occur if a wire rope sling snaps during use.

About Kennedy Wire Rope and Sling Company

At Kennedy Wire Rope and Sling Company in Texas, we’ve been providing manufacturers, steel companies, oil companies, and more with high-quality wire rope slings for every heavy lifting job for more than 40 years. We are headquartered in Corpus Christi with additional locations in San Antonio and Houston. We manufacture and deliver wire rope slings, fall protection equipment, rigging products, electric chain hoists, and more. As the leading supplier of wire rope, rigging hardware, slings, and other products, we are committed to giving our customers a level of quality and customer satisfaction that they can rely on for years to come.

Shop Our Collection of Wire Rope Slings Today

To choose the appropriate type of wire rope sling, a complete understanding of the applications and the various types are needed. Work with the team of experts who know this product better than anyone. At Kennedy Wire Rope & Sling Co, we offer a variety of wire rope slings in addition to advice on the proper application of each. We also provide rigging supplies, fall protection equipment, electric chain hoists, and more. Check out our collection of wire rope slings today to place an order or get in touch with us if you have any questions.